Quaker Oats Seed to Spoon Tour

/fit friends!

i went on a super cool trip last month🙌🏽.

i kissed my babies goodbye before heading to catch my flight✈️.

by the way, you guys gave some good guesses, but absolutely nobody figured out what city i was in after my IG Stories poll, lol.

i flew to Cedar Rapids, Iowa with 8 other AMAZING bloggers from all over the US for the Quaker Oats “Seed to Spoon” tour! i was so grateful to have been included in this bunch of crazy talented women to tour the world’s largest oat mill. the Quaker team was extremely gracious and gave us the inside scoop on how those classic oats go from “Seed to Spoon”.

upon our arrival to the hotel, we were each given a thoughtful, personalized Quaker tote bag of goodies!

such a kind gesture! i hope to pass that Texas cutting board down to Kosi.

meeting the ladies was a great honor and i absolutely enjoyed sitting across from and chatting with Ellie Krieger during our welcome dinner! she was super sweet and her face lit up as she spoke about her daughter💕.

we all got a kick out of this ‘errythang Quaker’ dinner menu! adorable!

d-licious from start to finish.

this was our view from dinner of the Quaker mill! our hotel was the perfect walking distance. thankfully, the rain cleared all the way up by the next morning in time for our tour.

dinner was at 6:30pm but i got hungry again around 10pm. so, i ordered some hummus and pita bread instead of the french fries i really, really wanted 🍟.

i called Hubs and the kiddos to tell them goodnight so i could hit the sack and get ready for our tour the next day.

an uninterrupted, full night of sleep had this mama feeling so refreshed! breakfast was delivered to our rooms and of course it was a steaming bowl of Quaker Old Fashioned Oats with brown sugar and berry topping options (i used them all💁🏽).

i’ve made a special Instagram highlight for the tour i’d love for you to check out!

after breakfast, we went over to begin the tour! this mill was built in 1873; it’s also the world’s largest oat mill and hosts approx. 900 employees.

everyone was extremely hospitable to us. this was our first tour guide who has been with Quaker for over 20 years! he led us to a conference room where we met a few more members of the Quaker team.

they showed us these oats, which is how they arrive to the mill. the first step is to remove the outer layer to get a groat, which is the edible part. a groat is just an “oat without a coat.'‘

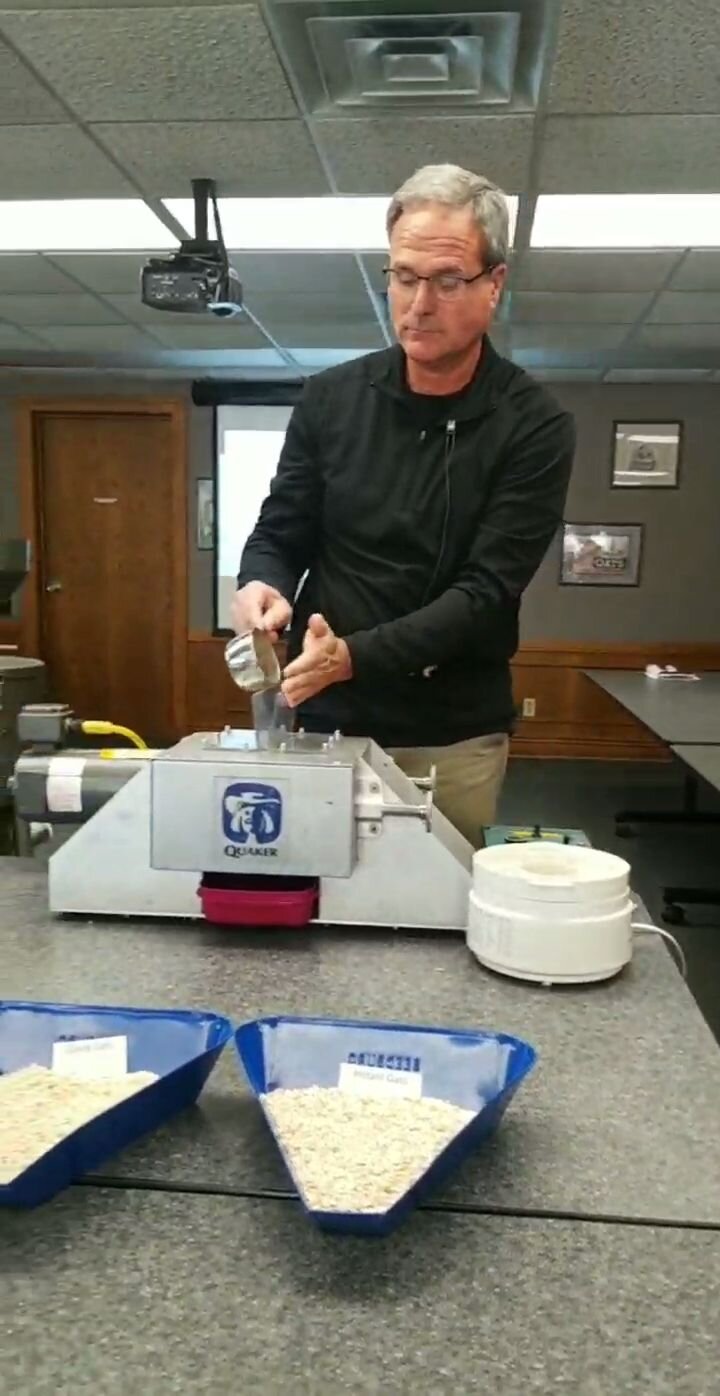

once the “coat” is removed (we attempted to remove the coat by hand and it took us forever…thank God for machines) a representative illustrated an example of what happens in the mill on a much smaller scale.

to make the different varieties of oats, once the coat is removed, the oats are steamed and poured between two rollers which flattens them out. they are then cut to the desired variety.

suited and steel toe booted!

we had to wear steel toed foot covers, hair nets, head phone / microphone systems to communicate over the roaring of the machines, and a hard hat before going out into the mill.

on the move! it felt like we were in a movie for a second! had to get this #girlpower shot.

our first stop was the grading lab. this is also the oat crop’s first stop once it arrives to the mill. the crop is divided into smaller samples and then tested and either given a pass or a fail. the expert grader is specifically looking for moisture, size, and composition to make sure they are high in quality. Quaker works with approx. 400 direct growers who grow about 50% of Quakers oats and they use about 20 varieties of oats in the products made here!

the oats spend a little time in a kiln which is where the toasted flavor comes from. on our tour, i asked what the temperature of the kilns were, and our guide replied, “HOT!” lol! the temperature is specific to Quaker Oats and their processes.

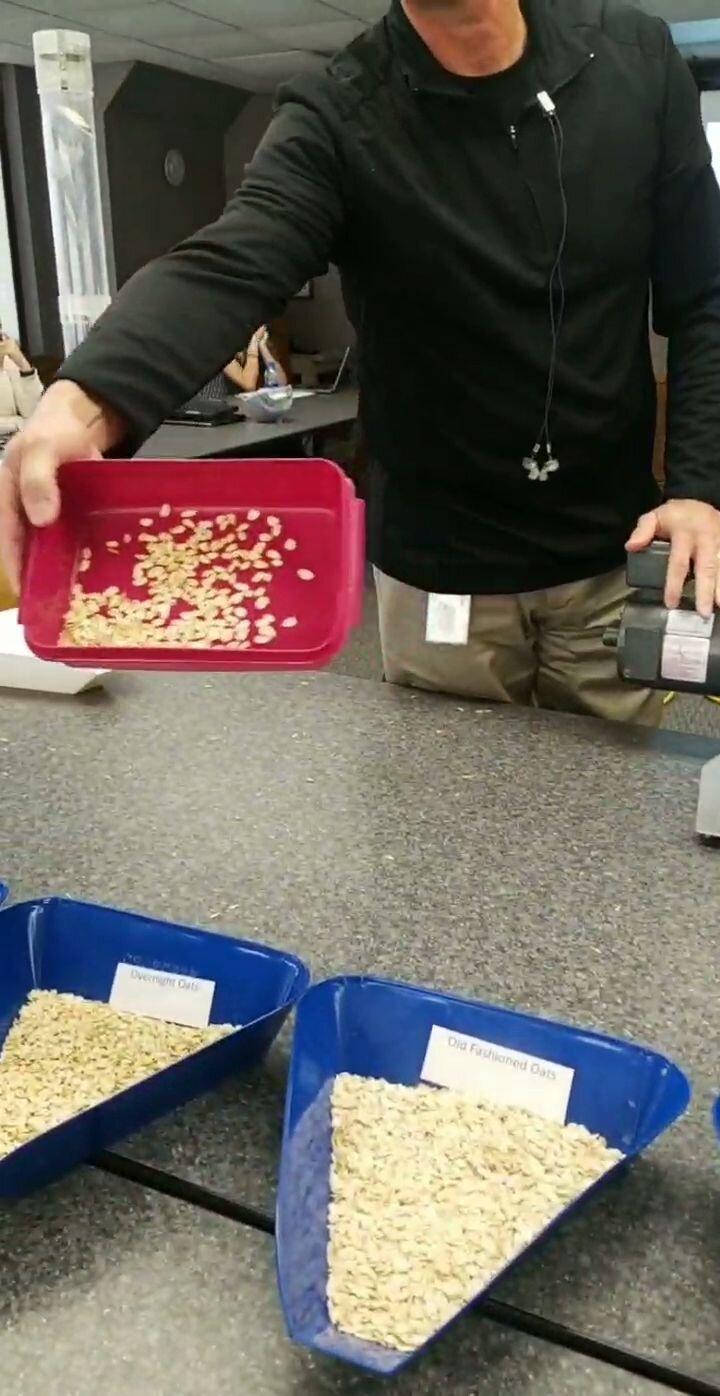

after kilning, we were able to see the rolling, cutting, and flaking processes the oats go through to become old fashioned, steel cut, or instant oats before they hit your breakfast table!

which one is your favorite? what kind to you buy and eat the most?

since some of the steps in these processes are unique to Quaker, understandably there are some areas we were unable to photograph. approximately 170 tubes are filled per minute and up to 3.6 million pounds of oats are produced in a DAY! #wow

also, no oats are wasted! they either become pet feed, and some are also sent to the University of Iowa for research.

after the tour concluded, we went back to the conference room for lunch!

what a fun, informative trip! i grew up on Quaker Oats and it was definitely an honor and pleasure to see where they are made!

and…i can’t stay at the Double Tree and not receive one of their famous cookies! I took it home to my babies🍪.

happy friday to you and thanks for reading!